Status and control (special GRBL version needed) My test bed.

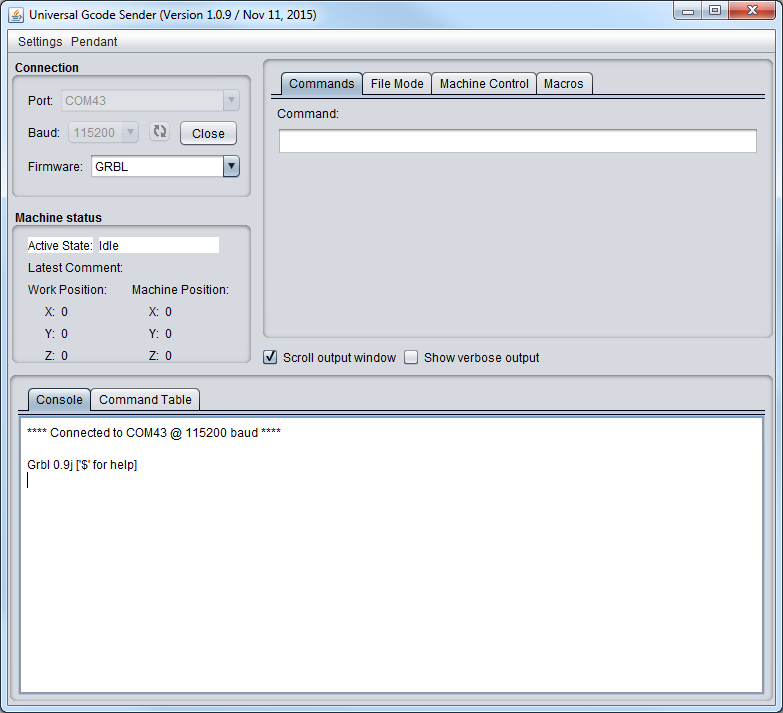

FEED rate in COM CNC window Controlling a 2nd GRBL-Hardware Supports 4th axis (A, B, C, U, V or W). Trademark machine Control Cabinet (Fanuc, Siemens-Sinumeric, Mazak CNC Software. real time display GRBL states (in COM CNC window) Check limits of GRBL setup - max. It is essentially the standard for open source CNC machines. GRBL is used to power thousands of different CNC routers, lathes, mills, lasers and more. GRBL CNC Machine, Arduino UNO CNC Machine, Driving Stepper Motors with GRBL Software. To A Post Processor is a unique driver specific to a CNC machine. What is GRBL GRBL is free, open source software for controlling the motion of machines that move, that make things, or that make things move, and runs on wide variety of microcontrollers. The purpose of the research is to find a simple design and of low cost CNC machine frame for industrial machines usage and to discuss results and the quality of low cost CNC machines. 3-axis CNC frame system is to locate the tool in the work area of the machine by 3-axis distributed as X, Y and Z in three different directions for two dimensions CNC machines. This system is used as a CNC frame for three different machines, laser cutting machine, CNC milling machines and 3D printing machines. And software main parts, Arduino Integrated Development Environment IDE, Inkscape and IntelliG-code. Designed to send GCode to CNC machines, such as 3D milling machines. Your CNC can only connect to one controller at a time.

Grbl controller software serial#

Software-wise, you first need a hex code (quick to google). This is a free and open-source program that talks to your CNC by a serial USB connection and.

Grbl controller software drivers#

This paper analyses the CNC stages to create full function of CNC machine as simple as possible using the main hardware parts, microcontroller, stepper motors, stepper motor drivers and power supplies. This is an offline CNC GRBL Controller for 3018 Pro, 3018, 2418, and 1810 that will. This paper examines the possibilities to create a low cost and less complexity CNC machine frame system as an alternative to support small and medium enterprises. And CNC machines usage yet is expensive and costly. The most of manufacturing processes need CNC machines to produce high quality products with high accuracy.

0 kommentar(er)

0 kommentar(er)